fuel consumption monitoring

& control function

CAST Engineering Ltd. offers fleet owners complete fleet management solutions to fully control & manage various types of fleets.

We provide premium solution and excellent service to all our customers. Precise and accurate fuel and telematics data is our constant and uncompromising target.

Our customers claim savings of 20-30% on the average for their fleet operation & maintenance.

Rich fuel monitoring feature incorporated in our Fleet Management Platform is enabled by 99.2% accurate fuel-level sensors.

CAST Engineering Ltd. has incorporated quality management certificates ISO 9001: 2015 and ISO / IEC 27001: 2013

Products

Our cloud solution is a web based server available for our customers 24/7/356. Due to modular functions structure the client may choose only the features relevant for their business.The approach guarantees tracking system flexibility and makes it accessible for any client, whatever tracking devices the company utilizes.

NEW FUEL LEVEL SENSOR OMNICOMM LLS 30160

The new Omnicomm LLS 30160 fuel level sensor with digital interface has a tamper-proof one-piece body, a new ultra-strong metal protection tube and increased protection against electrostatic, electromagnetic and conducted interferences

DIGITAL FUEL LEVEL SENSOR LLS-AF 20310

Digital fuel level sensor LLS-AF 20310 with analog/frequency output The sensor has an adjustable analog output, wherein the output voltage does not depend on supply voltage.

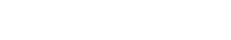

EXPLOSION PROOF FUEL LEVEL SENSOR LLS 20230

Explosion proof fuel level sensor LLS 20230 with serial output RS-232/EIA-485: the sensor is intended to be used on special types of vehicles or stationary fuel storage facilities and tanks, if the place of installation could be defined as the Potential Explosive Zone

LIQUID LEVEL DISPLAY SET

CAST Engineering Ltd. provides specially designed equipment to enhance the functionality of Omnicomm LLS sensors and your fuel management experience. From LLD Indicators to terminals and converters, the company provides everything you need to get set up and regain control of your fuel expenses.

TYRE PRESSURE MONITORING SYSTEM

TPMS systems measure the pressure in individual tyres, using sensors mounted on the wheel rim, on the inside of the tyre and can be applied to all types of LCVs and HDVs.

Automated load measuring system

The ALMS is fully autonomous and automated load measurement system. The core of the system is on-board ALM computer. Special load sensors are providing information to ALM computer for each axis.

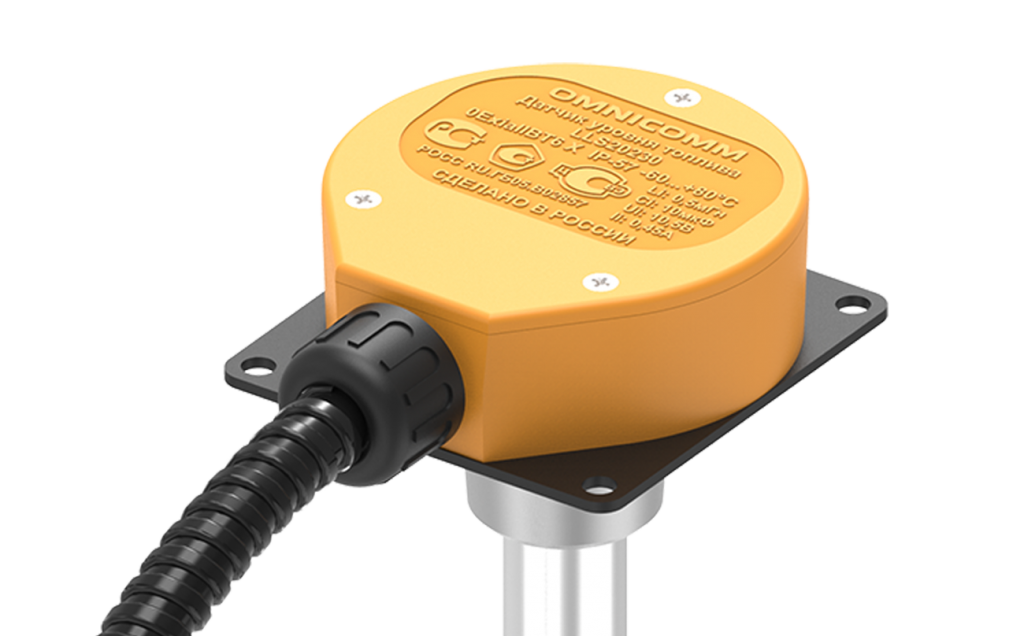

Automated remote temperature system

Automated Remote Temperature System (Wireless Temperature Sensor) is created for industrial monitoring systems and fridge transport fleets (trailers).

Special Projects

You can check all our special projects to see how can we help to grow you business faster and smarter

DIGITAL MILK FACTORY

Digital Milk Factory is an ambitious innovative project whose main aims are:

- Visualization of all factory processes.

- Optimization of processes and avoidance of any time-based weaknesses in the production.

To implement the ambitious “Digital Milk Factory” project our team needed to develop a truly universal system based on our cloud service in combination with reliable and cost effective sensors. Our capable team was able to create a comprehensive solution, which satisfied every project specification.

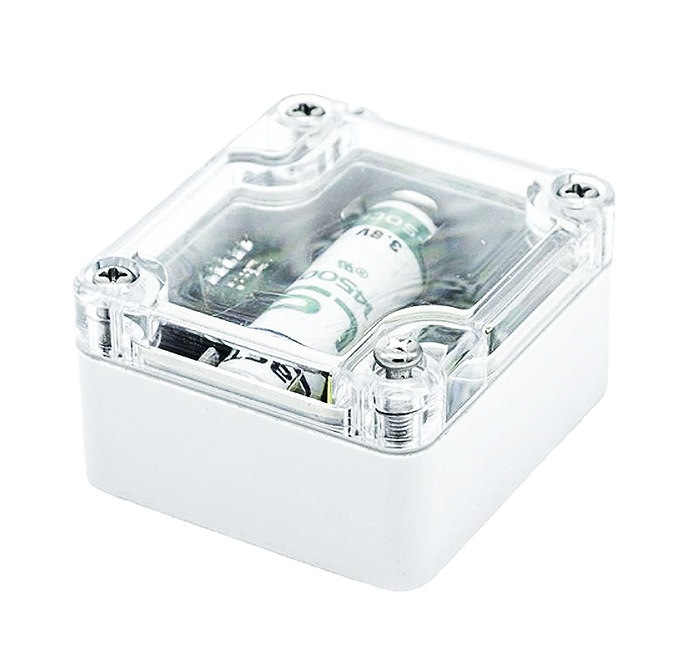

Diesel Generators

Our daily work and experience with the platform has provided to us a new services – a special diesel generators monitoring application has been launched.

Having the experience to operate and read out different signals from different types of sensors, our engineers have added a new value to our service: Monitoring and control of parameters of diesel generators and alarm states.

Deutsche Bahn

For many years, we are focusing on challenging and perspective projects. Our brand new project is now feel at home even in the railway transportation industry.

In this particular case, DB Cargo Bulgaria was focused on maneuvering locomotives for heavy copper smelting industry. They contacted us to cope with the following issues: